FEM: Mesh quality and body simplification (Part 4) - Mesh Quality

Have ever you asked: How to check the mesh quality in FEM? What are the criteria to consider to evaluate the mesh quality? In this topic, let's brifly to explain some concepts to have a good mesh quality and how to control it.

-

Elements distribution

How much

more homogeneous is the mesh, better. It means: similar type of elements and

non-distortion of the elements shape, regular distribution, elements with

similar size and smooth transition of sizes, continuity of nodes between parts

transitions.

Figure 1 - Element distribution comparison.

At left a mesh more homogeneous and below, quantitative element quality

analysis. Most of them have more than 88% of quality criteria.

-

Elements Transition

There are some regions in the body

which a smaller element is required while for others, not so small elements are

enough. Due to this sizing difference, there are transitions regions from

smaller to bigger elements. The softer is the transition, better will be the

mesh quality.

Figure 2 - Comparison of element transition.

At left a fast transition and at right a smooth transition.

-

Node anchorage

In most of the meshing strategies,

nodes are anchored on edges and on vertexes. If there are more than two vertexes

in an edge, the nodes will necessarily consider them and a distortion on the

mesh can appear due that the node must be at this point. So, to avoid extra

elements and distortion of mesh, a continuous edge is recommended in the CAD

model.

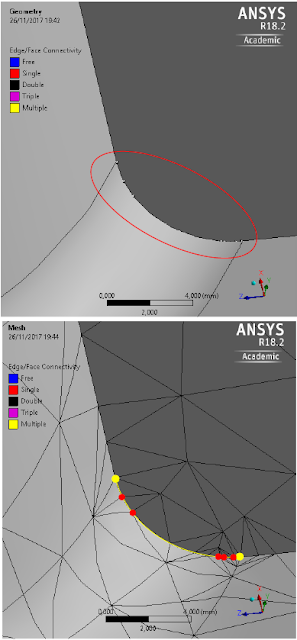

Figure 3 - Example of nodes anchorage on an

edge and how extra vertexes disturbs the mesh.

-

Connection between bodies

Some problems made by

several bodies need to be interpreted as an only one big body (rigid, without

relative movements). In this case, the mesh must be continuous in all system

and share the same nodes (shared topology) on the edges where there are the

connections between each body.

Figure 4 - A problem when the bodies need to seem as just

only one.

Figure 5 - At left, a system without shared

topology, the mesh is generated independently for each body. And at right with

shared topology, the mesh is continuous and considers all system.

-

Mesh density in proper regions and geometry

simplification

There are some regions that cause an increment

of the mesh density. These are shaped transition regions, like fillets,

chamfers, small details, markings, holes, recesses etc. As is known, how much

small is the element size, bigger is the results accuracy, but by another hand,

more computing processing is required. The point is, that there are some

regions where we will have maximum tensions and is only in these regions that

is interesting we have accuracy and a proper mesh density (local mesh

refinement), while that a big density in other regions are not necessary.

Sometimes is not possible to know where are

these regions, so one first interaction is required to identify where is

necessary to the mesh have its density incremented or not.

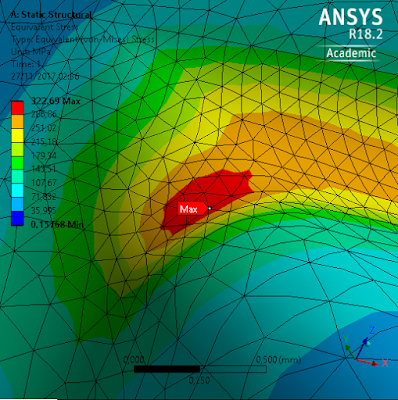

Figure 6 - After the first interaction, is identified

the region of maximum tension, wherein the mesh density needs to increment.

Figure 7 - The maximum tension in just a

node is a signal that the mesh density must increase.

Figure 8 - After increased of the mesh

density, the maximum tensile is distributed by several nodes so as provide more

reliability of the result.

For other regions with low tensions, where do not need an

increment of the mesh density, bigger elements can be used without losing the

resulting quality and even increase the speed of solution with fewer elements

and nodes. It is achieved with geometry simplification, removing regions that

naturally creates small elements (fillets, chamfers, small details, markings,

holes, recesses etc), but do never remove fillets and chamfers in regions of

maximum stress as will be explained at section “Number of elements and

convergence”.

Figure 9 – The original body

created a mesh with 24813 nodes and 14525 elements.

Figure 10 - The simplified body created a

mesh with 4007 nodes and 2137 elements, resulting in an 85% reducing.

- Geometry repairs

Is important we always check the CAD

quality before do the meshing. It´s necessary because some inconsistencies or

redundancy could be in the geometry. Some examples of problems in the geometry:

gaps between surfaces or missing faces, extras vertex on edges, extra or redundancy

of edges or surfaces, some residue due CAD operations etc. There are FEM

software that identifies these problems and solve automatically. For other

situations, some manually geometry manipulation is necessary.

Figure 11 - Examples of geometry failures.

From left to right: Surface gaps, face missing and extra edges.

Figure 12 - A very small unnecessary surface

that generated small extra elements, disturbing the mesh. Probably due to

residue of CAD operations.

-

Number of elements through the

thickness

In a body

subjected to bending, there is a recommended rule that a minimum of 4 linear

elements or 2 superior order elements should have through the thickness of the

body. But if a membrane stress can be observed, with a slight change in stress

(tensile and compressive) magnitude through the thickness, only one element

through the thickness is enough. If the body has a thin wall, subject to

tensile and compressive stress on opposite sides, is recommended to reduce the

element size only in critical regions, to do not create excessive unnecessary

elements [Autodesk].

Figure 13 - For a body subjected to bending,

a minimum of 4 elements through the thickness. But witch a slight change in stress

(tensile and compressive) like right one part, only one element through the

thickness is enough. FONT: Autodesk.

Comments

Post a Comment